The car business is going through a groundbreaking movement, driven by the rising interest for economical and practical transportation arrangements. At the core of this change lies the lithium battery, a key empowering influence for the moderateness and far and wide reception of electric vehicles. As mechanical progressions and imaginative assembling processes reshape the business, the connection between battery production and battery materials assumes a significant part in driving this change.

The Center of Electric Vehicles: Lithium Batteries

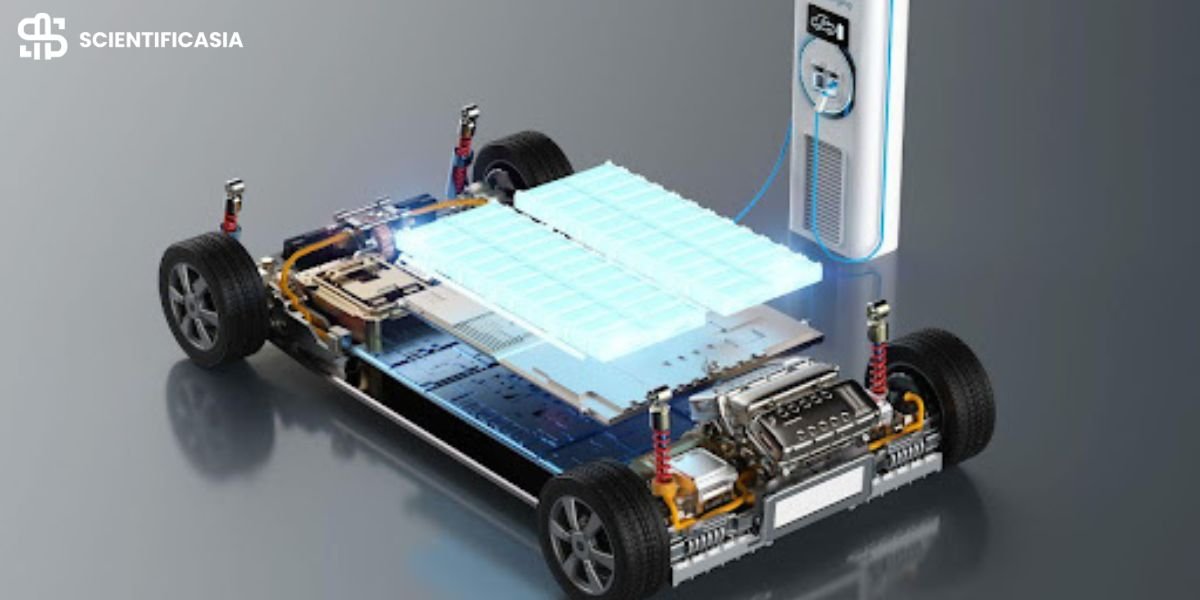

Lithium-particle batteries have turned into the norm for fueling electric vehicles because of their prevalent energy thickness, life span, and capacity to proficiently re-energize. These batteries permit vehicles to accomplish noteworthy reaches on a solitary charge, overcoming any barrier among electric and customary gas powered motor (ICE) vehicles with regards to common sense and comfort.

The reasonableness of electric vehicles to a great extent relies upon the expense of their batteries, which generally made up a critical part of the vehicle’s general cost. Be that as it may, upgrades in battery production procedures and the enhancement of battery materials have prompted a consistent decrease in battery costs throughout the long term, making electric vehicles more open to the typical buyer.

Progresses in Battery Production

The development of lithium batteries has advanced quickly, powered via mechanization, economies of scale, and mechanical leap forwards. Production lines devoted to assembling these batteries are enhancing cycles to increment yield while lessening waste. Key headways include:

Robotization in Assembling: Computerized sequential construction systems limit blunders and further develop productivity, considering the production of top notch batteries at a lower cost.

Normalization: Uniform battery plans improve on production, decrease costs, and empower similarity across different vehicle models.

Reusing and Reuse: Reusing utilized batteries to separate important materials has turned into a foundation of manageable production, further bringing down costs.

The Job of Battery Materials

Lithium batteries depend on a mix of materials to convey elite execution, including lithium, cobalt, nickel, manganese, and graphite. Developments in material science play had a critical impact in making batteries more effective and reasonable:

Lithium: As the essential part, lithium guarantees high energy thickness. Endeavors to source lithium more economically and diminish reliance on difficult-to-arrive at stores are working on cost and natural effect.

Cobalt Decrease: Cobalt is one of the most costly and morally moving materials to source. Makers are effectively decreasing cobalt content for nickel or different other options, driving down costs.

Arising Choices: Scientists are investigating cutting edge materials, like strong-state electrolytes, to make more secure and more proficient batteries with even lower production costs.

Overcoming any issues Among Cost and Maintainability

The moderateness of electric vehicles isn’t simply a consequence of further developed battery production yet in addition a coordinated work to offset cost effectiveness with natural obligation. Reasonable obtaining of battery materials, close by imaginative reusing rehearses, guarantees that the ascent popular for electric vehicles doesn’t come at an impractical natural expense.

Moreover, administrative approaches and motivations pointed toward helping electric vehicle reception have sped up interests in battery advancements. These drives frequently incorporate sponsorships for innovative work, tax breaks for electric vehicle purchasers, and backing for the production of broad charging framework.

The Eventual fate of Reasonable Electric Vehicles

As the worldwide spotlight on diminishing fossil fuel byproducts escalates, lithium batteries will keep on energizing the ascent of reasonable electric vehicles. Developments in battery production and forward leaps in battery materials are set to make electric vehicles more interesting to a more extensive crowd, guaranteeing they stay a feasible choice to ICE vehicles.

Arising advancements, for example, strong state batteries, guarantee significantly more noteworthy enhancements in energy thickness, wellbeing, and cost-adequacy. Combined with a consistently extending charging network and expanded public consciousness of the natural advantages, the fate of electric vehicles looks brilliant.

End

Lithium batteries have turned into the foundation of the electric vehicle insurgency, changing what was once a specialty market into a standard peculiarity. By improving battery production processes and advancing with battery materials, the business is consistently defeating difficulties of cost and execution. Thus, reasonable electric vehicles are as of now not a far off dream yet a feasible reality for millions around the world, preparing for a cleaner and more economical future.