5G forces your printed circuit boards to handle frequencies and power densities that standard manufacturing used to ignore. With the FCC opening up millimeter-wave bands—specifically 28, 37, and 39 GHz—the physical materials you choose become the most critical part of the design.

The reality is that a substrate or fab method that cruised along at 2–5 GHz will likely fail at 28 GHz. You face higher risks of signal loss, thermal runaways, and spotty performance. So, how do you make sure your board survives the jump to 5G? It comes down to selecting the right material and tightening your fabrication controls.

Why Dk and Df Make or Break Your 5G Signal

High-frequency boards live or die by their substrate. Specifically, we’re looking at two critical specs: Dk (dielectric constant) and Df (dissipation factor). Think of Dk as how fast your signal travels through the board, while Df tells you how much of that signal gets eaten up as heat.

In the 5G world, you generally want a Dk under 4 and a Df sitting comfortably below 0.005. Standard FR-4 just can’t keep up here. With a Dk around 4.2 and a Df near 0.02 at high frequencies, FR-4 acts like a brake on your signal. Compare that to specialized 5G laminates—like PTFE—that offer a sleek Dk of ~3.5 and a Df as low as 0.0009.

So, why do these tiny decimals matter?

Because at gigabit speeds and millimeter-wave frequencies, small inefficiencies turn into massive performance hits. Here is how the wrong material fights against your design:

● It kills your range: High Df sucks energy out of the signal. Every 0.001 increase in Df translates to precious milliwatts wasted as heat rather than reaching the antenna.

● It ruins timing: A higher Dk slows down electromagnetic waves. In high-speed circuits, this propagation delay throws off the timing alignment across your traces.

● It creates heat: When a material runs “lossy,” that wasted energy has to go somewhere. It becomes heat, which can drift the material properties and cause instability.

As Rogers Corporation points out, designing millimeter-wave circuits starts with the material because you simply can’t force a low-frequency board to perform out of its league. The numbers back this up. At 28 GHz, a standard FR-4 board might suffer an insertion loss of about 0.8 dB/cm. Swap that for a low-loss option like Rogers RO4350B, and you drop to ~0.3 dB/cm.

That is a 62% reduction in signal loss just by changing the substrate. By balancing Dk and Df correctly, you give your design a fighting chance to hit its bandwidth targets instead of wasting energy heating up the device.

Hybrid Stack-ups: 5G Performance on a Real-World Budget

Building an entire 8-layer board out of pure PTFE laminate will give you superb RF performance. It will also blow your budget.

Top-tier materials from brands like Rogers or Taconic are engineered for speed, but they command a premium price. The smarter move for many 5G designs is a hybrid stack-up. The logic is simple: use high-performance materials only where you need them, and standard materials where you don’t. Why pay for exotic laminates on layers that just carry power planes or low-speed digital logic?

Putting Theory into Practice

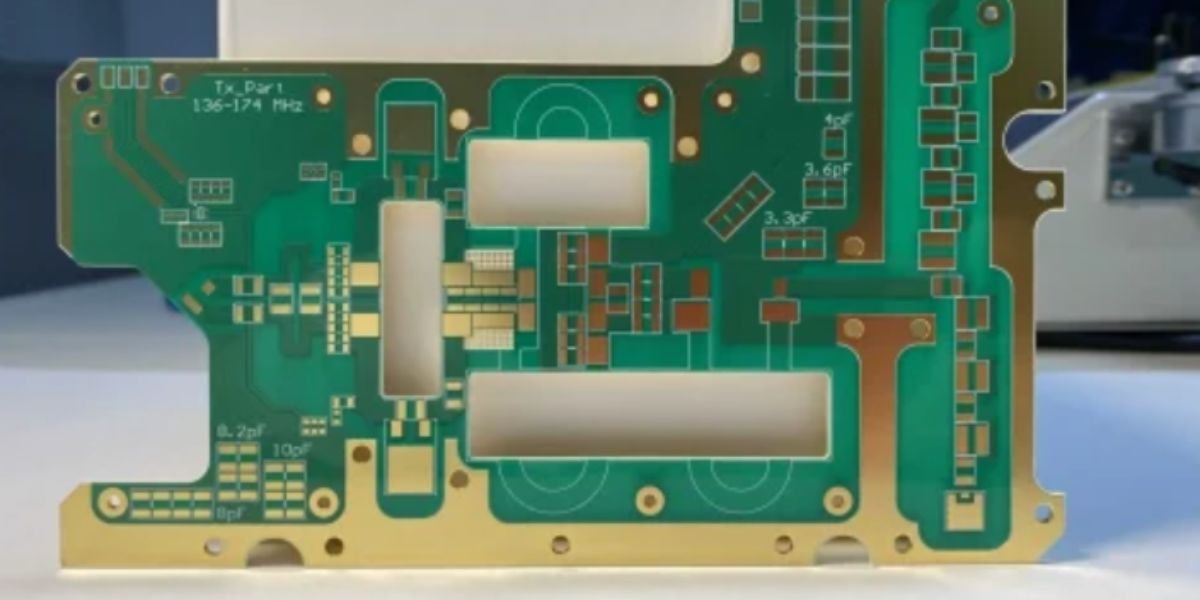

Take a typical 5G base station board. You will often see the outer layers—where the critical mmWave signals and antenna traces live—built with low-loss laminates like Rogers RO4350B. Meanwhile, the inner layers stick to economical FR-4 or high-speed epoxy.

As data from Sierra Circuits suggests, this mix hits the sweet spot. You get the signal integrity required for 5G without the heavy price tag of a full-PTFE build.

The “Sandwich” Problem

However, you can’t just slap any two materials together. You are effectively building a sandwich with different physical properties, and the biggest headache here is the Coefficient of Thermal Expansion (CTE).

If your RF layer expands at a different rate than your FR-4 layer when heated, the board acts like a bimetallic strip. It warps, twists, and can eventually crack the copper plating in your vias. To stop that from happening, we have to pick materials that play nice together.

● Match the properties: Engineers often favor the Rogers RO4000 series because its CTE aligns closely with standard FR-4.

● Watch the bonding: Standard prepregs don’t always stick well to PTFE cores. You might need specialized adhesive systems, like Rogers 2929 bondply, to ensure the layers fuse firmly without delaminating.

A Final Note on Manufacturing

Mixing materials adds complexity to the manufacturing floor. This is where your relationship with the fabricator becomes critical. We strongly recommend involving them early in the design phase—especially when specialized Rogers PCB fabrication is involved. They can guide your material pairing and layer arrangement to ensure the board isn’t just electrically sound, but can actually be built without issues.

Stop Treating PTFE Like Standard FR-4

If you have ever worked with Rogers or Taconic materials, you know they don’t behave like standard FR-4. These PTFE-based or ceramic-filled laminates are softer, waxier, and far more finicky. Treating them like regular epoxy boards is a recipe for disaster.

To successfully build a board from these materials, a fabricator needs to adjust their entire approach.

The Drilling Challenge

PTFE is notoriously soft. If a shop attacks it with standard high-speed drill parameters, it doesn’t cut cleanly; it smears. The heat from a dull or fast-moving bit can actually melt the resin, clogging the hole wall. Since traditional chemical desmear processes don’t work well on PTFE, the drill has to be perfect the first time.

Experienced fabricators switch to new carbide bits for every job—never resharpened ones. They also slow things down significantly. For instance, while FR-4 can handle high speeds, drilling PTFE might require a surface speed of just ~150 ft/min. This conservative approach keeps the material cool and ensures a clean, round hole.

The Plating Challenge

Here lies the real make-or-break moment. Teflon is designed to be non-stick. That is great for frying pans, but terrible for keeping copper inside a via. If you try to plate directly onto untreated PTFE, the copper will likely peel off.

To fix this, the whole wall must be chemically activated. Quality shops typically use Sodium Etching (a chemical process highly effective for pure PTFE) or Plasma Etching (using ionized gas) to strip away fluorine atoms and create a rough surface that copper can actually grip.

Why Experience Matters

Rogers PCB fabrication isn’t just about buying the right material; it’s about the process control behind it. This is where specific expertise counts. For example, manufacturers like PCBAIR implement rigorous workflows specifically to tame these “unruly” materials, prioritizing the sensitive requirements of the PTFE layers over standard FR-4 in hybrid builds.

When your manufacturer knows how to handle these nuances, your design’s performance on paper actually materializes in the real world.