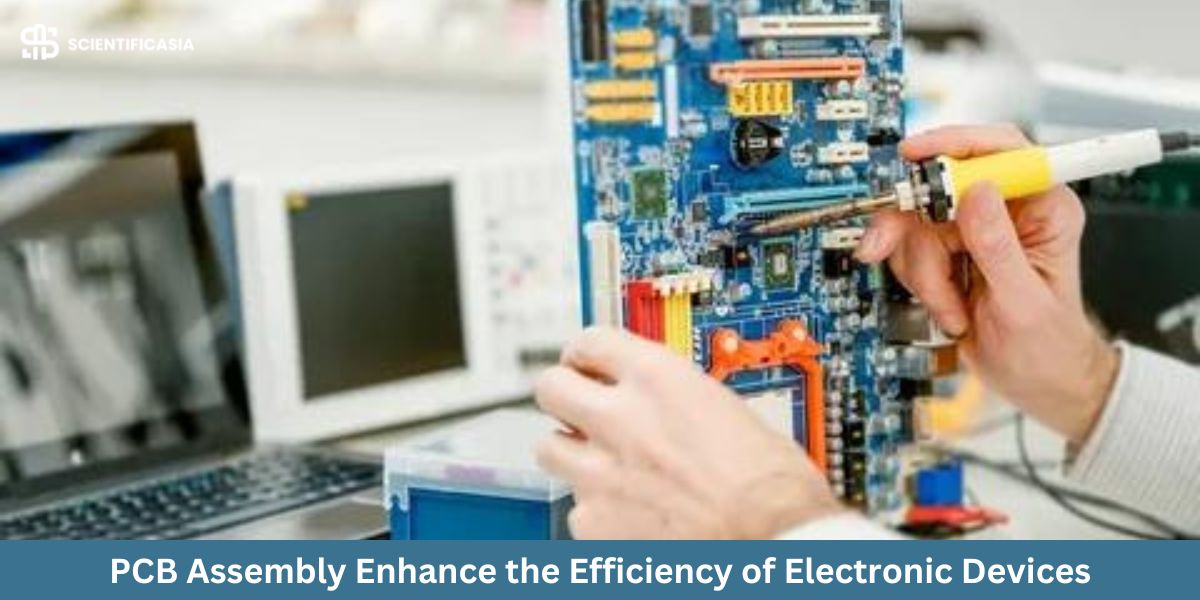

Printed Circuit Board (PCB) assembly is a critical cycle in the manufacturing of electronic devices. Because with regards to electronic devices PCB plays a crucial role in enhancing their efficiency. But here the question arises how does this fastidious assembly method contribute to overall performance of these electronic gadgets?

It includes the position and fastening of electronic parts onto a PCB, making a practical electronic circuit. Let’s explore how PCBs improve the single integrity, design efficiency, thermal management, fabricating process and the general dependability and strength of electronic gadgets. Each of these prospects are intertwined to make a consistent operation that keeps your gadgets effective and working properly or seamlessly. OurPCB, a leader or a forerunner in PCB manufacturing, has succeeded in providing top-notch PCB assembly services similar to these.

Streamlining Component Placement

PCB assembly together considers exact and productive placement of electronic parts or components. This kind of automated machinery, such as pick-and-spot machines, precisely positions parts on the board. This effective accuracy guarantees that every part or component is set in the ideal position, decreasing the risk of blunders and upgrading and enhancing the overall productivity and functionality of the device. The exact placement of the components are very important if you want to maintain the signal integrity and diminish the electromagnetic obstruction. Both of these functionalities are crucial and fundamental for the productive activity of electronic devices.

Enhancing Reliability and Durability

The utilization of high-quality and excellent materials and advanced techniques of soldering in PCB assembly works on the unwavering quality and sturdiness of electronic gadgets. These advanced methods are getting better day by day for the functionality of gadgets. Improvements take place with each module. Components are safely patched onto the board, reducing the risk of loose associations or connections that could prompt gadget failures. This solid connection upgrades the lifespan of the gadget as well as guarantees predictable or consistent performance and execution. Also, the performance and greater functionality of the device are the main things that are vital for both customer electronics and industrial applications.

Improving Thermal Management

Effective thermal management is very crucial and basic for the performance and life span of electronic devices. Because the performance is everything in the device. The worth of a device can be lower or higher just because of its effectiveness and performance. PCB assembly strategies, for example, the utilization of warm vias and heat sinks, assist with dispersing heat. By overseeing heat dispersion, PCBs keep parts from overheating, which can degrade the performance or execution and lead to untimely failure. Effective thermal management guarantees that electronic devices work inside safe temperature ranges, improving their effectiveness and dependability.

Reducing Signal Loss and Interference

Modern PCB assembly methods center around limiting signal misfortune and interference. The PCB’s design and the proximity of the device components are just two examples of the various variables and factors that can have an impact on high-recurrence signals. By cautiously planning and designing the layout and utilizing methods such as establishing and protecting, PCB get-together can lessen signal debasement and electromagnetic interference (EMI). This results in more clear signal transmission and works on improvements in the overall performance of the electronic devices. Signals can be improved by reducing EMI electromagnetic interference and RFI radio frequency interference. As signal crosstalk is minimized and shielding techniques are implemented can efficiently mitigate the integrity of signals. The result of this is clear signal transmission across the PCB, and ultimately, the overall performance of electronic devices can be improved.

Enabling Miniaturization

One of the critical advancements in PCB assembly is the capacity to help the miniaturization of electronic gadgets. As technology advances, there is a developing interest in more modest, more reduced devices. PCB assembly procedures, like surface mount technology (SMT), take into account the situation of more modest parts with higher accuracy. This miniaturization not only makes gadgets more compact and portable but also enhances and upgrades their effectiveness by diminishing power consumption and further developing execution.

Facilitating Mass Production

PCB assembly is fundamental for the large-scale manufacturing of electronic devices. Automated assembly production systems can create huge volumes of PCBs with consistent quality and accuracy. This scalability and adaptability are pivotal for satisfying the needs of the consumer gadget market, where enormous amounts of gadgets should be made rapidly and effectively. Large-scale manufacturing capacities additionally assist with decreasing the cost of manufacturing devices and making electronic gadgets more reasonable for buyers.

PCB Assembly Process Impacts the Overall Cost of Manufacturing

When you consider the PCB assembly process in manufacturing electronic devices, it significantly influences overall costs. Performance and functionality of electronic devices are important, and considering these while manufacturing may reduce any other term of device. So, PCB Assembly gathers all their best methods and techniques to provide all in one solutions to their valuable consumers. PCB assembly methods can streamline production, reduce errors, and optimize resources, leading to cost savings and improved competitiveness in the market.

Read more:

Smart Home Devices: Ensuring Home Safety and Cleaning