Air-cooled chillers are pivotal in ensuring smooth operations in industrial cooling equipment’s vast and varied landscape. York industrial air-cooled chillers stand out for their efficiency, reliability, and technological advancements. They are critical in maintaining temperature control for processes and facilities, providing a compelling advantage in manufacturing environments. Below, we will delve into the benefits these chillers offer and how they contribute to optimal manufacturing performance.

Understanding the Role of Air-Cooled Chillers in Manufacturing

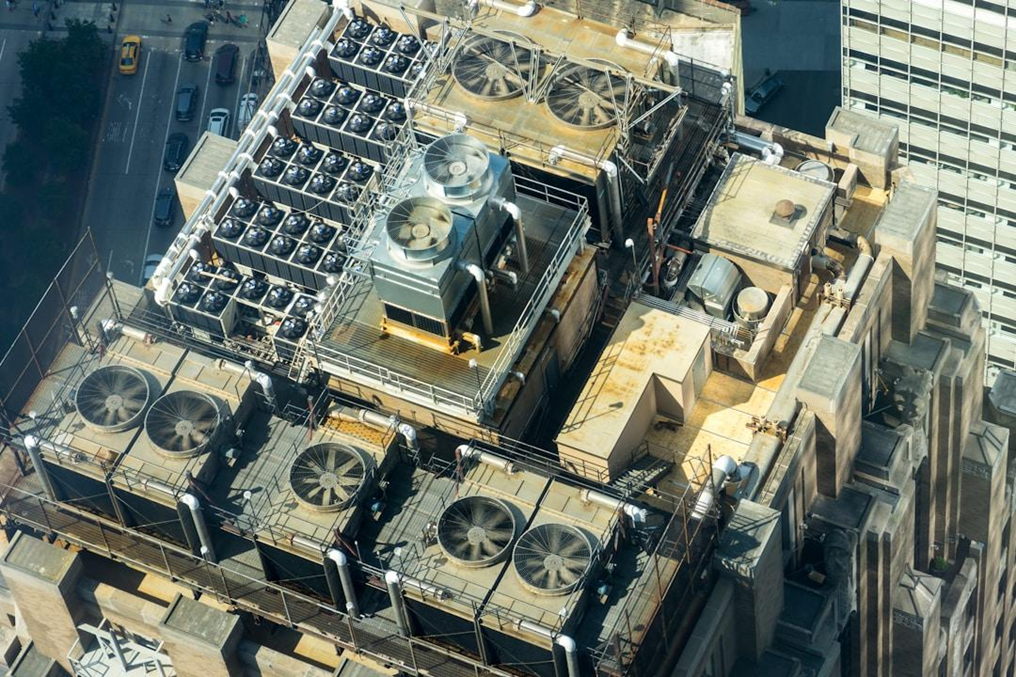

Precise temperature control is essential for product quality and safety in manufacturing. Air-cooled chillers remove heat from processes or the facility environment through refrigeration technology. Unlike water-cooled chillers, air-cooled variants do not require a cooling tower, which makes them preferable for locations where water resources are scarce or where water use needs to be minimized.

These chillers draw in ambient air and use it as the medium to dissipate heat from the condenser. This reduces the temperature within machinery or the facility, protecting sensitive equipment and products from heat damage. Air-cooled chillers offer a compact and practical solution for facilities with space constraints or those seeking a simplified installation.

Air-cooled chillers are used in various sectors, from food and beverage manufacturing to pharmaceuticals. They are essential for processes that require strict temperature regulations, such as chemical reactions, machinery operations, and storage of temperature-sensitive goods. Thus, a dependable chiller system is a cornerstone of modern manufacturing, protecting integral processes and investments.

An example of a leader in this industry comes from the York industrial air-cooled chillers, renowned for their durability and advanced technological integrations. As these chillers improve, they become more capable of meeting the rising demands of industry, ultimately becoming integral to production efficiency.

Energy Efficiency of York Industrial Air-Cooled Chillers

Energy consumption is a significant concern for manufacturers, not only from a cost perspective but also in terms of environmental impact. Air-cooled chillers are engineered to offer higher energy efficiency than many other cooling systems. This efficiency can significantly reduce operational costs and help companies adhere to stricter energy use regulations.

Advanced compressor technology and variable speed drives allow these units to adjust cooling output to match demand. Such adaptability avoids unnecessary energy expenditure, often resulting from less sophisticated equipment operating at constant, full capacity despite variable cooling needs.

Furthermore, the design of these chillers often includes heat recovery options, allowing waste heat to be repurposed rather than expelled. This capture and reuse of energy can further reduce a facility’s total energy consumption, leading to a smaller carbon footprint and enhanced sustainability profiles for businesses.

Investing in high-efficiency air-cooled chillers supports environmental stewardship and translates to long-term savings. Manufacturers can realize lower utility bills and reduced maintenance costs due to better system performance.

Improving Operational Reliability with York Chillers

Reliability in manufacturing operations is non-negotiable, as unexpected downtime can be incredibly costly. York’s air-cooled chillers are built to offer outstanding reliability, featuring robust components and design. This reliability extends the cooling system’s lifespan and secures continuous manufacturing operations.

Regular maintenance and intelligent controls are key to keeping these chillers running smoothly. Advanced control systems equipped in chillers can provide predictive analytics and diagnostics, allowing for proactive maintenance and swift resolution of any issues before they lead to a breakdown.

The chillers’ construction considers ease of service, with components strategically placed for quick access and replacement. Such thoughtful engineering reduces the downtime associated with maintenance, repairs, or part replacements, ensuring manufacturers can depend on their cooling systems daily.

Overall, York industrial air-cooled chillers provide manufacturing facilities with a dependable cooling solution that enhances operational continuity. Their advanced technology, reliability, and cost-effective performance make them a valuable asset for sustaining high productivity levels in demanding industrial environments.